|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 스프링용

DSR의 스프링용 스테인리스 와이어는 우수한 기계적인 성질(인장강도, CAST, HELIX)을 일관되게제공하고 있으며, 이는 아래 제시된

스프링 와이어 규격에 따라 와이어 원재료(ROD)부터 마지막 제품까지 엄격한 품질관리를 하고 있으며, 용도에 따라 분류된 적합한 Coating을

만족하고 있다.

| |

| |

| ● 표면처리 및

용도 |

| 분류 |

기호 |

강종 |

선경(mm) |

용도 |

| S-CO |

WPA |

AISI 302, 304, 304N1, 316 |

0.20 ~ 7.00 |

일반 스프링용 |

| WPB |

AISI 302, 304, 304N1 |

0.20 ~ 6.00 |

| WPC |

AISI 631J1 |

0.20 ~ 4.00 |

| Bright |

WPA |

AISI 302, 304, 304N1, 316 |

0.15 ~ 7.00 |

광택이 필요한 Forming 가공 및

스프링용 |

| WPB |

AISI 302, 304, 304N1 |

0.15 ~ 6.00 |

| Ni-Co |

WPA |

AISI 302, 304, 304N1, 316 |

0.20 ~ 1.60 |

정밀 스프링용고속자동 COIL용 |

| WPB |

AISI 302, 304, 304N1 |

| WPC |

AISI 631J1 |

| Ni-Co Bright |

WPA |

AISI 302, 304, 304N1, 316 |

0.15 ~ 1.60 |

| WPB |

AISI 302, 304,

304N1 | |

| |

| ● 제품규격 |

| 선 경(mm) |

허용차(mm) |

인장강도

N/mm2(kgf/mm2) |

| A종 |

B종 |

C종 |

| AISI 302 - WPAAISI 304 - WPAAISI 316

- WPA |

AISI 302 - WPBAISI 304 - WPB |

AISI 631J1-WPC |

| 0.16 |

±0.005 |

1650 - 1900 |

2150 - 2400 |

1950 - 2200 |

| 0.18 |

| 0.20 |

| 0.23 |

±0.008 |

1600 - 1850 |

2050 - 2300 |

1930 - 2180 |

| 0.26 |

| 0.29 |

| 0.32 |

| 0.35 |

| 0.40 |

| 0.45 |

±0.010 |

1950 - 2200 |

1850 - 2100 |

| 0.50 |

| 0.55 |

| 0.60 |

| 0.65 |

1530 - 1780 |

1850 - 2100 |

1800 - 2050 |

| 0.70 |

| 0.80 |

| 0.90 |

±0.015 |

| 1.00 |

| 1.20 |

1450 - 1700 |

1750 - 2000 |

1700 - 1950 |

| 1.40 |

| 1.60 |

1400 - 1650 |

1650 - 1900 |

1600 - 1850 |

| 1.80 |

±0.020 |

| 2.00 |

| 2.30 |

1320 - 1570 |

1550 - 1800 |

1500 - 1750 |

| 2.60 |

| 2.90 |

1230 - 1480 |

1450 - 1700 |

1400 - 1650 |

| 3.20 |

| 3.50 |

±0.030 |

| 4.00 |

| 4.50 |

1100 - 1350 |

1350 - 1600 |

- |

| 5.00 |

| 5.50 |

| 6.00 |

| 6.50 |

±0.035 |

1000 - 1250 |

- |

| 7.00 | |

| |

| ● 포장사양 |

|

|

| 선경(mm) |

Packing (F X B X W : A) |

App. W/T(kg) |

| 0.16 ~ 0.44 |

DIN 200 |

12 |

| DIN 250 |

20 |

| DIN 355 |

40 |

| SH390 |

15 |

| SH460 |

35 |

| SH460 |

35 |

| 0.45 ~ 0.79 |

400x300x200(60) |

50 |

| 450x300x240(60) |

100 |

| 700x380x250(60) |

250 |

| 0.80 ~ 1.59 |

500x400x300(60) |

100 |

| 600x400x390(60) |

300 |

| 700x380x250(60) |

350 |

| 1.60 ~ 1.90 |

500x400x300(60) |

100 |

| 600x400x390(60) |

300 |

| 700x380x250(60) |

350 |

| 1.91 ~ 4.00 |

500x400x300(60) |

100 |

| 600x400x390(60) |

300 |

| 750x380x480(130) |

500 | |

| |

| 선경(mm) |

Coil I.D (Inch) |

App. W/T(kg) |

| 0.20 ~ 0.30 |

8 |

10 |

| 0.30 over ~ 0.40 |

8 |

10 |

| 0.40 over ~ 0.50 |

8 ~ 10 |

10 |

| 0.50 ~ 0.80 |

12 |

20 ~ 25 |

| 0.80 ~ 0.90 |

16 |

25 ~ 35 |

| 0.90 over ~ 1.00 |

16 |

25 ~ 50 |

| 1.0 over ~ 1.80 |

16 |

25 ~ 50 |

| 1.80 over ~ 2.30 |

24 |

100 |

| 2.30 over ~ 4.00 |

24 |

100 ~ 200 |

| 4.00 over ~ 7.00 |

24 |

200 ~

500 | |

| |

| 선경(mm) |

Coil I.D (Inch) |

App. W/T(kg) |

| 1.91 ~ 7.00 |

24 |

910 | |

| |

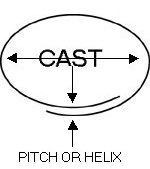

| ● CAST & HELIX(PITCH) |

| The most important thing to make high quality spring is how to control cast

& helix. As our specifications are based on lots of customer's demands, we

have ever made control of it as follows: |

| |

|

|

| Dia(mm) |

Coil I.D(Inch) |

Cast(mm) |

Helix(mm) |

| 0.20 ~ 0.40 |

8 |

200 ~ 300 |

30 under |

| 0.40 over ~ 0.50 |

8 |

200 ~ 300 |

| 10 |

250 ~ 370 |

| 0.50 ~ 0.80 |

12 |

300 ~ 450 |

| 0.80 ~ 0.90 |

16 |

400 ~ 600 |

| 0.90 over ~ 1.00 |

50 under |

| 1.00 over ~ 1.80 |

| 1.80 over ~ 2.30 |

24 |

600 ~ 900 |

60 under |

| 2.30 over ~

7.00 | | | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|